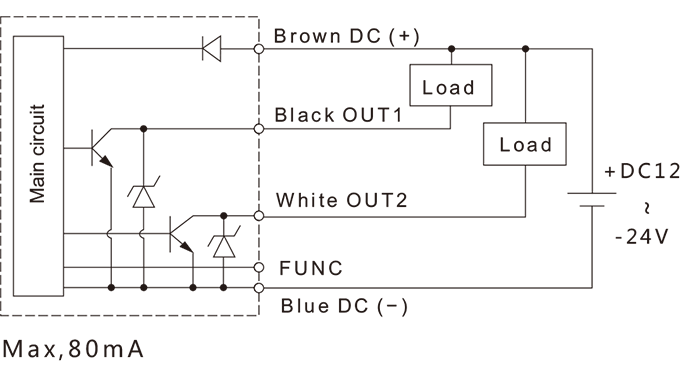

40 mA or less

28 V (With NPN output)

2 V or less (With load current of 80 mA)

28 V (With NPN output)

2 V or less (With load current of 80 mA)

CE marking,RoHS,UL/CSA

±0.2%F.S.±1digit

Air, Non-corrosive gas, Non-flammable gas

±0.2%F.S.±1digit

Air, Non-corrosive gas, Non-flammable gas